ProAct 2.0

Give your machine the right conditions

The key to avoiding unnecessary downtime and costly repairs is to service your machine properly before problems arise. Our proactive maintenance concept is designed to do just that - keep your machine in top condition through planned inspections and proactive service measures.

With ProAct 2.0, you get a complete solution where we work together to ensure that your machine is always ready for new challenges. We carry out regular inspections and ensure that the maintenance plan suits the needs of your machine. Of course, we always use original Komatsu parts and consumables to ensure the highest quality. Together with your own daily supervision, we make sure your machine always performs at its best.

ProAct 2.0 also gives you better insight into your service costs and a complete documentation of your machine's history. What's more, thanks to your personalised field stock, you'll always have spare parts close at hand, giving you extra peace of mind.

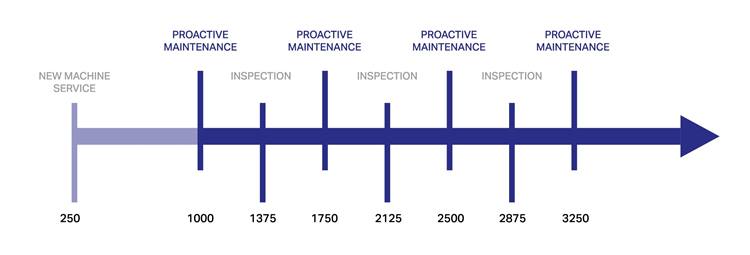

750 h service intervals give you more time for production